Thanks yall, yeah it used to have a pretty nice paint job, that is something that I'll also be redoing in the near future. Body isn't as straight now, but I really dig the look of a nice paint job over mashed metal.

Although I haven't explicitly stated it before, this has always been sort of a retro build, using basic old school parts, tools and tech. Generally speaking, most of the parts on the truck are things that could have been bought in the 80's to early 90's, right down to the Q78-15 TSLs. With that in mind, I've decided to keep most of my engine mods to that time frame as well going forth.

So, all that to say I'm going from 21st century camshaft technology back to 1980's camshaft technology. I decided to go with an Edelbrock Performer Plus cam, this is what most would describe as an "RV" cam back in the day. As a quick little side note, back in the 60s/70s/80s the term Recreational Vehicle (RV) was broadly used to describe anything from jeeps to 4wd pickups to powerboats, and yes, even motorhomes. So an RV cam isn't really a cam meant for your Winnebago, although it could be used for such. Generally speaking an 'RV' cam is around 204/214 duration at .050", and in the mid .400" lift range, tons of low end torque, power range from idle to 5000rpms. All around a good match for the aforementioned applications.

Specs on the original cam:

Comp Extreme 4x4 X4250H

250/258 Advertised Duration, 206/214 Duration at .050, .448" Intake/.483" exhaust lift, 111* lobe separation

New cam:

Edelbrock Performer Plus 2182

270/280 Advertised Duration, 204/214 Duration at .050, .448" intake/.472 exhaust lift, 112* lobe separation

So on paper these cams look very similar, and performance wise they are within a few hp/ft-lbs of each other but there are some differences.

First off, when comparing cams generally you compare the "duration at .050"" numbers, that means the duration starting measurement at .050" of valve lift. 204/214 @ .050 is a very low end torque cam, start getting up into the .224/.234 range and your looking at more mid and top end hp. The first number is always the intake side, second number is exhaust side. You also compare the valve lift numbers, the higher the lift the more possible air flow and more hp.

"Advertised Duration" isn't very useful for comparing cams per say, but the numbers do mean something. Generally Advertised Duration is measured at about .006" valve lift which is when the valve is just starting to open. This is a trick I just learned: If you subtract duration at .050 from the Adv. duration you come up with a number which correlates to how aggressive the ramp profiles are.

For example:

Comp X4250H is 250/258 adv and 206/214 @ .050, subtract those numbers and you come up with 44/44

Edelbrock 2182 is 270/280 adv and 204/214 @ .050, subtract those and you get 66/66

The smaller the number the faster the valve is being pushed open and slammed shut, the larger the number the more gently it is. So the Edelbrock cam is 'lazier' off the seat, but will promote better valvetrain stability/longevity and quieter vavletrain operation. The Comp cam on the other hand is pushing the limit of how fast a flat tappet cam can open and close the valve, this gives a little more power and a more aggressive and racier sound.

So I picked the Edelbrock cam for the above mentioned reasons, plus I had the matching Edelbrock Performer intake, and lastly I could purchase it through Advance auto and use my speedperks rewards to get it for cheap.

I also picked up a matching set of valve springs (it's important to use the correct valve springs that are recommended for your cam, ask me how I know, lol) and a double roller timing chain set.

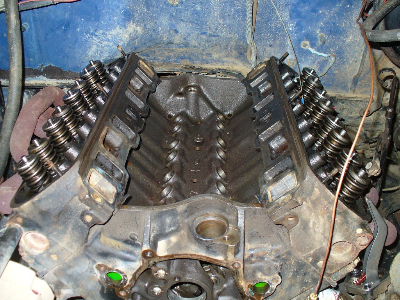

Here you can see how clean this motor is inside, I didn't clean this at all, just dabbed up the oil and spilled coolant. Running a hot enough thermostat (195* in my case) is one of the keys to keeping your motor free from gunk and sludge:

- P1020635.JPG (246.12 KiB) Viewed 28436 times

Here's a trick for camshaft installation and removal, screw a long bolt into the end of it for a handle. You must be very careful to gently and smoothly remove and install a cam to avoid nicking the cam bearings, which if bad enough can cause a loss in oil pressure:

- P1020639.JPG (151.38 KiB) Viewed 28436 times

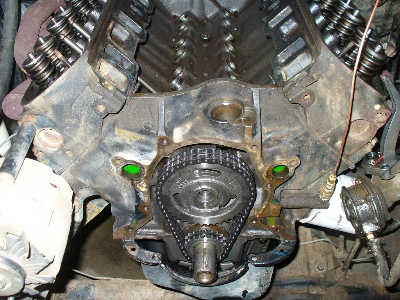

Removed the old cam, installed the new cam (with proper break in lube applied to lobes and lifters) and here I'm "degreeing in the cam." Basically you are using the degree wheel bolted to the end of the crankshaft along with a pointer to see what the timing is in degrees vs valve lift. This will tell you a) if your cam timing is off (mine was off, more on that later) and b) how well the cam is ground to spec:

- P1020643.JPG (243.79 KiB) Viewed 28436 times

In that last pic I'm reusing the stock style timing chain, which turned out to be retarding the cam by about 4*, which will hurt performance. This could be attributed to wear, or possible the stock OEM replacement wasn't a 'straight up' timing set. A lot of the smog era motors from the 70's and 80's used a retarded timing set to improve emissions, but at the sacrifice of power. So, I installed my new Edelbrock double roller timing set, rechecked everything and the cam was dead on spec this time:

- P1020644.JPG (239.93 KiB) Viewed 28436 times

With everything right in the camshaft world I went to buttoning up the motor, installed the timing chain cover, intake manifold, accessories, etc. This time I splurged for the Fel-pro 'race' gaskets for the intake and it was a good choice, they are about 3x the cost but are better quality and have bigger port openings. These heads and intake manifold don't have huge intake ports (though we did open them up a little) but even still the stock gaskets barely clear the openings. This means if you don't get everything including the gaskets perfectly aligned your gaskets protrude into the ports disrupting air flow, I found my old ones were by about 1/8" in some ports hence going with the better/larger gaskets this time. Also to note, throw away the gaskets for the ends of the intake manifold and use a good bead of black RTV instead, you'll never get a good seal here with gaskets. RTV around the water passages as well, just for good measure:

- P1020646.JPG (252.6 KiB) Viewed 28436 times

One last thought, Terry and I built this motor the first go round basically as quickly and as cheaply(<----Alright Terry, you can say I told you so

) as possible. While I have found a few problems in our original engine build most of them could have been avoided if I had spent a little more money and a little more time researching things. The bottom end is still very solid, with excellent compression (190psi !) and decent oil pressure, just tidying up some things I should have done the first time around.

More to come soon, including setting up Ford lifter preload with roller rockers, carb and ignition tuning, a new 3" exhaust system, and maybe some pulls on the dyno