Page 1 of 2

Pinion tightening

Posted: Thu Sep 23, 2010 11:40 am

by Riversoflucidity

So I have a Dana 30 with crush sleeve.. I replaced the pinion bearings and such, and Re-assembled everything. The dealership told me to start tightening it down before the carrier went in, so I did that to about 50 foot pounds. Now the shafts are in and tires are on, and it's on the ground and I want to finish tightening it down, however it won't budge or get any tighter and the pinion is still there wiggling around. Anyone know a good way to get it tightened down???

Thanks,

Bryan

Posted: Thu Sep 23, 2010 11:50 am

by BadAssEddie

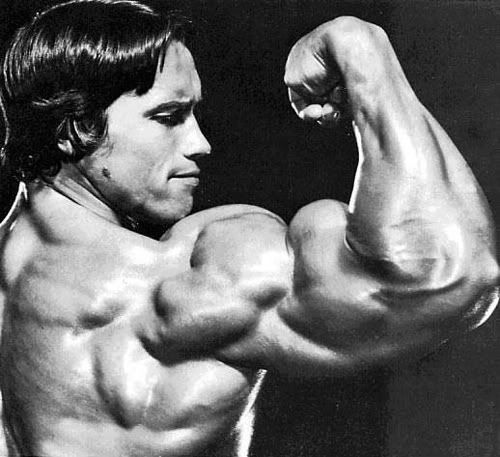

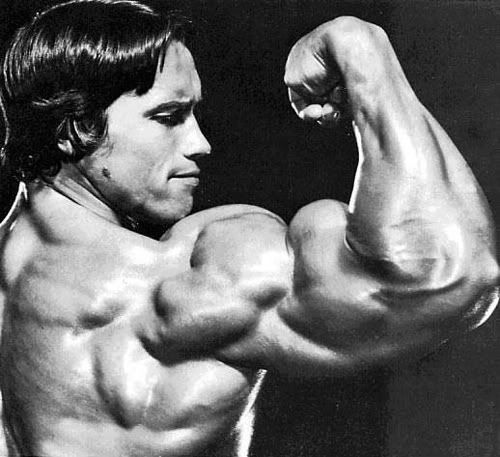

Crush sleeves require hundreds of foot pounds of torque, so I believe all you need is one of these:

and one of these:

Posted: Thu Sep 23, 2010 12:20 pm

by shmoken875

My old dana 30 didn't use a crush sleeve

It was all shims. Are you talking a dana 35? You'll need a 4' pipe wrench on the yoke (harbor freight) and a mega torque wrench (or just figure your pull with a huge breaker bar)

Posted: Thu Sep 23, 2010 12:30 pm

by willhf1011

You dont need to use anything precise to start the crush sleeve. an impact or monster bar works fine. however, once it is started its very easy to overdo it. I use an impact on them and once you see theyve started either turn the gun down or resort to a shorter breaker bar and go in small increments, checking the bearing preload each time. also, you cant really check bearing preload with the ring gear in.

Posted: Thu Sep 23, 2010 1:14 pm

by Riversoflucidity

The newer TJ's and ZJ's have the crush sleeve, the XJ's haven't ever used them for some reason.

Ok, looks like i'll be pulling everything apart again this weekend and hope it will tighten correctly.. Would it be possible for me to drive the jeep a quarter mile to a shop and have them do it? It's pretty difficult to get enough room to tighten the pinion nut down that much.

I do have a cordless impact that says it goes to 200 foot pounds, however it didn't even seem to make a difference. I'm definitely stumped on this whole thing.

Bryan

Posted: Thu Sep 23, 2010 2:09 pm

by BadnewsCJ

Riversoflucidity wrote:The newer TJ's and ZJ's have the crush sleeve, the XJ's haven't ever used them for some reason.

Ok, looks like i'll be pulling everything apart again this weekend and hope it will tighten correctly.. Would it be possible for me to drive the jeep a quarter mile to a shop and have them do it? It's pretty difficult to get enough room to tighten the pinion nut down that much.

I do have a cordless impact that says it goes to 200 foot pounds, however it didn't even seem to make a difference. I'm definitely stumped on this whole thing.

Bryan

200 ft lbs is not all that much, especially in the realm of air impact wrenches

I second Rants advice, that's how we did the rear in my old CJ.

If you do drive it then pull the shafts out. I wouldn't want to drive very far with a pinion "wiggling around"

Posted: Thu Sep 23, 2010 3:20 pm

by Riversoflucidity

I'll try Randys idea first then. should I pull the carrier and do it that way, or should I leave the carrier in? If that doesn't work, then I guess i'll have to take it to the shop.

Bryan

Posted: Thu Sep 23, 2010 3:27 pm

by BadAssEddie

you need the carrier out to check bearing preload.

Posted: Thu Sep 23, 2010 3:55 pm

by Riversoflucidity

How do I check the bearing preload?

Posted: Thu Sep 23, 2010 4:22 pm

by zach119

Put the torque wrench on the pinion nut and turn it and see how much resistance there is. For this you need an inch pound wrench and you can look up the specs for what your preload should be. This is very important because the crush sleeve is what sets the bearing preload.

Posted: Thu Sep 23, 2010 5:10 pm

by willhf1011

Depending on how far the shop is you might ought pull the pinion instead. If you pull the carrier then your shafts will be resting on the inner seals when you drive and you will probably tear them. If you pull the shafts too you wont have the stub shaft in the unit bearing to hold it together.

A crush sleeve can take a shit ton to start, but a dana 30 shouldn't be too bad. a real 200 ft-lbs would do it I would think but it could take more. Once it starts though, be very slow and careful with it. Use a bar type in-lbs torque wrench (the kind that bend with a needle) to see how much drag the pinion has when you are turning it (with no carrier obviously) You have to turn it smoothly an consistently to get an accurate reading (its not the initial reading to get it started moving, but rather the constant force required to keep turning it) new bearings should generally be set to about 20-30 in-lbs I believe. About half that for used bearings.

Posted: Thu Sep 23, 2010 5:18 pm

by Riversoflucidity

Both the inner and outer pinion bearings are new, as well as the crush sleeve.

I've never done this axle gear bearing thing before, so what your saying is that;

1) pull carrier

2) hold yoke down with monkey wrench

3) tighten the hell out of it to get the sleeve to begin to crush

4) then as it compresses check the bearings be putting the torque wrench on the pinion nut to check?

From what a guy in the Jeep club in Nova told me;

"New bearings should be 12-15inch lbs, Reused bearings 6-9 inch lbs"

5) keep tightening until it no-longer can wiggle back and forth then finish torquing it down?

Sorry for all the questions, I've got it all disassembled in my driveway here in Radford and need it finished as soon as possible so I can go home next weekend for a wedding.

Bryan

Posted: Fri Sep 24, 2010 11:18 am

by shmoken875

Riversoflucidity wrote:Both the inner and outer pinion bearings are new, as well as the crush sleeve.

I've never done this axle gear bearing thing before, so what your saying is that;

1) pull carrier

2) hold yoke down with monkey wrench

3) tighten the hell out of it to get the sleeve to begin to crush

4) then as it compresses check the bearings be putting the torque wrench on the pinion nut to check?

From what a guy in the Jeep club in Nova told me;

"New bearings should be 12-15inch lbs, Reused bearings 6-9 inch lbs"

5) keep tightening until it no-longer can wiggle back and forth then finish torquing it down?

Sorry for all the questions, I've got it all disassembled in my driveway here in Radford and need it finished as soon as possible so I can go home next weekend for a wedding.

Bryan

http://www.yukongear.com/Downloads/Tech ... ctions.pdf

you're right on the preload

I think steinberg has a needle style in-lb torque wrench, if you ask nicely and give him a sixer of yuengling he may let you borrow it.

Posted: Fri Sep 24, 2010 12:02 pm

by zip ties

If all else fails you can always call Dr. Terry. He makes house call and does it right! I think he is very busy tho, and it will cost some $$, but well worth spending the money now then making it 50 miles down 81. Cause after replacing the pinion bearings you still need to check the backlash. And if that is out because your pinion depth changed slightly, that too would suck!

Posted: Fri Sep 24, 2010 12:58 pm

by Riversoflucidity

zip ties wrote:If all else fails you can always call Dr. Terry. He makes house call and does it right! I think he is very busy tho, and it will cost some $$, but well worth spending the money now then making it 50 miles down 81. Cause after replacing the pinion bearings you still need to check the backlash. And if that is out because your pinion depth changed slightly, that too would suck!

I am going to get it back up on the jack stands and try getting it tightened a bit, and if not I'll try to contact him. Is he on this forum? And if so can I get a number for him? Thanks

Bryan