I've got the following engine projects going on right now:

-top end upgrades to the 351w in my '79

-complete rebuild of a 2.3L Ford in my brothers CJ-2a

-complete rebuild of the L134 flathead in my CJ-3a

-minimum of a head gasket job, maybe a full rebuild of the 3.4L in my '97 4runner

So there can be plenty of pics and tech I can post as I work through these projects. Let me also say, I am by no means an expert in this subject, but I've been tinkering with motors in the off-road world for a few years now and have learned quite a bit. Terry also knows volumes on the subject of motor building and hopefully he will be adding to this thread as well (any of yall feel free to add tech also, I'm still learning everyday myself)

One thing I have discovered is there is very little tech info in books, on the web, or even from the companies that make the parts about building motors for off-roading. This became painfully obvious when I was talking to all the cam company tech lines a few weeks back and discussing my needs for a cam for my '79. Their specialty is drag racing, hot street/strip motors, etc, not chugging along through the woods at 500rpms.

Pic of the 363" Windsor that's in my '79, when it was freshly built:

The first step to any engine buildup is planning, so we'll start there. The type of wheeling we do (a mix of slow speed trails/crawling, combined with some high rpm hill-climbs and mudding) requires lots of low end torque, fast throttle response, and enough mid-range/top end power to really spool up the tires when needed. Generally we're looking to make power in the idle to 5000rpm range with a nice flat torque curve. To make that happen takes decent compression and good air flow (port velocity) at low to mid rpms.

I could write a bunch of boring stuff here about all the theory behind this, but instead I'll just give an example 'recipe' and we can discuss more of the specifics later:

Small-block V8 ~350-360ci Ford, Chevy, Mopar take your pick.

-9 to 9.5:1 compression ratio

-Stock iron heads with some port and bowl work, maybe a good 3-angle valve job, or aftermarket heads in the 160-180cc range (a lot of variables in the heads, we'll discuss that later)

-Low-end or "RV" style cam, about 204/214 duration at .050, about .450 lift, with straight up timing set

-Edelbrock Performer dual plane intake

-600cfm 4 barrel carb (or perferably a Q-jet) or fuel injection

-1 1/2" to 1 5/8" primary headers, shorty or full length

-free flowing 2.5" dual or 3" single exhaust

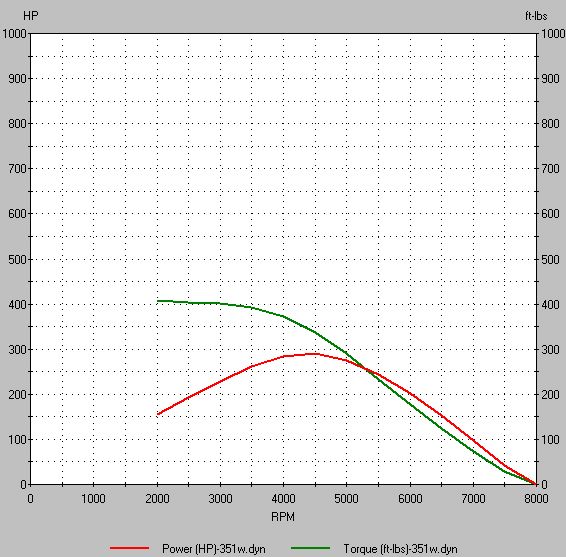

The above combo should make a dyno graph that looks something like this (this is just a desktop dyno generated graph, may or may not equate to real life numbers):

Boat loads of low end torque pulling all the way through mid range, and hp peaking around 4500.This is very close to the way the motor in my '79 acts and my current build specs are very similar.

363ci Windsor (351w bored .060" over)

-9.25:1 hyperutectic pistons

-stock crank and rods, reconditioned with all ARP chromoly fasteners

-E7TE casting iron heads, with a good bowl blending and mild port work

-Edelbrock Performer Plus 2182 cam, 204/214 duration at .050, .448/.472 lift

-Edelbrock Performer dual-plane intake

-Quadrajet carburetor

-Shorty headers

-3" single exhaust with good flowing muffler

-GM HEI ignition

This motor pulls hard all the way down to about 400rpms on the bottom end and up to about 4500 on the top. With my current cam It'll turn 5500, but it's not making much power that high and that's nearing valve float. Plenty of torque for most any crawling and enough power to spin Q78 swampers in third gear low range on the hill climbs. Also, smokes the tires all the way through first, second, and part way through third on the street, but we won't talk about that

I'm hoping to get it on the dyno soon so I can see what it's actually making.

Right now I'm mostly discussing standard V8 carb'd application because their common, cheap and easy to build, and mostly what I deal with. Also note that all the basics apply whether you have a 4, 6, or 8 cylinder, carb or fuel injection. Increasing compression, proper camshaft and good flowing head(s) is always a good start for performance. I'll try to post up some of the specifics on compression ratios, cams, intakes, heads and carbs and what works for our uses very soon.

) that prevent a good booster signal at lower engine speeds.

) that prevent a good booster signal at lower engine speeds.